Browse our removable products where you’ll find partials, cast partials, dentures and much more.

Ivotion® Milled Digital Dentures

Innovation Meets Excellence with Ivotion®

The Ivotion® system combines precision engineering with time-tested materials to create dentures that stand apart from processed or printed alternatives. Every denture is backed by advanced CAD/CAM technology, ensuring a superior fit, increased reliability, and consistently positive patient outcomes.

Complete Dentures

Conventional Denture –

Set-up 5 Days in Lab, Finish 5 days in Lab

Our conventional dentures are manufactured using Ivoclar denture base material and premium denture teeth from Vita (mould charts available upon request). The combination of our extensive experience and proven processing techniques results in a prosthesis with excellent fit, natural esthetics, and durability. Patient’s names are laser engraved on each case. Our standard denture includes palatal anatomy and general festooning.

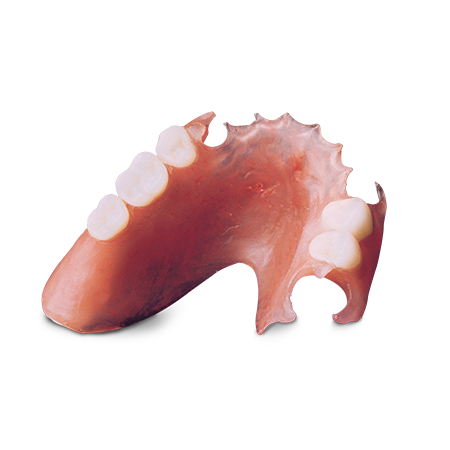

Removable Partial Dentures

Cobalt-Chrome Frame –

10 Days In Lab

All frames are manufactured with additive manufacturing technology. Ivoclar Probase acrylic is conventionally processed with premium denture teeth from Vita to complete the prosthesis. Unique physical properties of the alloy enable the technician to achieve sound, strong, resilient frames designed to fit and to function well during a long and useful life. Available with optional clear or tooth colored clasps.

- Superior additive manufacturing technology

- Professionally designed for patient’s individual needs

- Maximum fit and function

- Ultimate in durability and longevity

- Long clinical history of patient satisfaction

Duraflex™ – 7 Days In Lab

A metal-free RPD consisting of an advanced thermoplastic with a semi-crystalline polymer structure that is manufactured through a heat and injection process. Made with Vita denture teeth. In many cases it is possible to rebase, repair, and add teeth. Comes in a variety of shades.

Flex-Sil – 7 Days In Lab

Ideal for periodontally involved teeth, our gasketed partial denture offers a metal-free alternative to the cast partial denture. It is a patented tissue-bearing appliance featuring a soft elastomeric gasket that clasps the neck of each natural tooth.

Thermoflex® Clasps – 3 Days In Lab

Thermoflex® is an improved acetyl resin system with many benefits of metal free restorations. With its high abrasion resistance, flexibility and excellent tensile and shock strength, Thermoflex® is a performance material that delivers long lasting function. Used for clasps, complete partials, bridge work and more, Thermoflex® stands up to the forces that can fracture acrylics. Offering durable performance, excellent retention and 19 tooth and tissue colors for esthetics, THERMOFLEX® is the metal free material for removable restorations with ideal flexibility for multiple applications.

Visiclear Clasps – 3 Days In Lab

VisiClear/Thermoflex® is the ultimate choice for reliability and esthetics. VisiClear/Thermoflex® clasps are flexible, strong, and stain resistant; a great choice for your next dental appliance (Thermoflex® available in 8 shades).

Laser Welding Service

At Artisan Dental Laboratory we offer a range of laser welding services. With our laser welder we can add clasps, repair partials, join attachments and connectors, just to name a few possibilities. We also use the welder to create innovative solutions to individual case challenges, and to aid in the overall quality and fit of our bridges. A real problem solver! We are finding ways to fix cases that previously required remakes!